Products

-

Brown fused alumina sanding belt Blended fabric cloth base Water and oil resistant

Brown fused alumina belt

Brown fused alumina abrasive, blended fabric cloth base, medium density sand planting process

Specifications: customized on demand

Granularity: P24-P1000 -

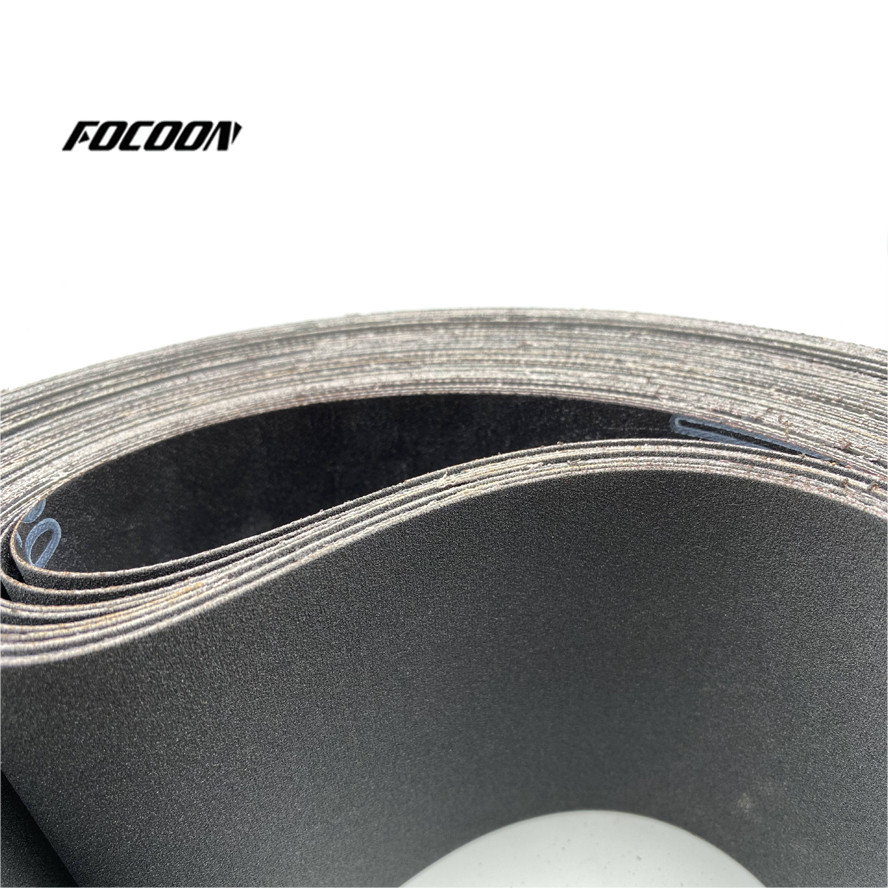

Silicon carbide sanding belt Cloth or Paper backing Wet and Dry

Silicon carbide belt

Material: silicon carbide

Specifications: customized on demand

Granularity: P24-P1000 -

Zirconia alumina sanding belt Medium/Heavy duty grinding

Zirconia Alumina Abrasive Belt

Material: Zirconia alumina abrasive, Waterproof polyester cloth, Electrostatic sand planting process

Specifications: Customized on demand

Granularity: P24-P320

-

Ceramic abrasive belt High grinding efficiency Wet and Dry

Ceramic abrasive belt

Properties: Ceramic alumina ore; Polyester fiber backing; Grinding aids added on the surface; Resin glue.

Particle size: 24, 36, 40, 50, 60, 80, 100, 120.

Size: support customer customization -

Diamond sanding belt High grinding efficiency Good durability

Diamond sanding belt is a coated abrasive product developed by using super-hard material (man-made diamond) as abrasive and adopting a new manufacturing process.

It has the dual advantages of the softness of traditional coated abrasives and the high hardness of diamonds.

Compared with traditional ordinary sanding belts, the biggest features of diamond belts are high grinding efficiency, good durability, good finish, high cost performance, and environmental protection advantages with low dust and low noise during use.

-

Brown fused alumina Nylon sanding belt Brown Blue Red color

This product is suitable for portable and desktop automatic grinding tools, with elasticity and small grinding force, which can improve the grinding pattern of the workpiece and is easy to replace and use. Compared with traditional abrasive tools, nylon abrasive belt has the following advantages: it can control the smallest amount of grinding, grinding depth, anti-clogging, and has the smallest probability of over-tolerance. The product continuously exposes new abrasive layers during the grinding process, and the grinding effect is good.

-

Silicon carbide Nylon sanding belt Black Green Gray color

This product is suitable for portable and desktop automatic grinding tools, with elasticity and small grinding force, which can improve the grinding pattern of the workpiece and is easy to replace and use. Compared with traditional abrasive tools, nylon abrasive belt has the following advantages: it can control the smallest amount of grinding, grinding depth, anti-clogging, and has the smallest probability of over-tolerance. The product continuously exposes new abrasive layers during the grinding process, and the grinding effect is good.

-

Types of sanding belt suitable for furniture polishing and grinding

In the production process of furniture products, wood needs to be grinded and polished, and brown fused alumina sanding belts and silicon carbide sanding belts are suitable for selection.

Brown fused alumina abrasives and silicon carbide abrasives on the surface of the sanding belt use the process of sparsely planted sand, and use cloth backing and paper backing according to the specific characteristics of the wood (density, humidity, oiliness, and brittleness).

-

Types of sanding belt suitable for metal polishing and grinding

According to the different metals being ground, and the different equipment used, choose different abrasives and cloth bases to match to achieve the optimal efficiency.

Optional sanding belt of different abrasive grain:Brown fused alumina,

Silicon carbide,

Calcined abrasives,

Zirconia alumina,

Ceramic abrasives ,

Accumulation abrasives. -

Types of sanding belts suitable for plates grinding and polishing

Grinding plates that require overload grinding, such as high-density board, medium-density board, pine, raw planks, furniture and other wooden products, glass, porcelain, rubber, stone and other products, you can choose silicon carbide sanding belt.

The silicon carbide sanding belt adopts shaping abrasives and polyester cloth base. The silicon carbide abrasives have high hardness, high brittleness, easy to break, anti-clogging, antistatic, strong impact resistance, and high tensile strength.

-

Types of sanding belt suitable for stone polishing and grinding

For grinding and polishing stone products, it is suitable to choose brown fused alumina sanding belt and silicon carbide sanding belt.

Brown fused alumina, silicon carbide and polyester cloth base, anti-clogging, anti-static, strong impact resistance, high tensile strength.

Mainly used in: natural marble, artificial marble, quartz stone, calcium silicate board and other composite materials.

-

Paper base sanding belts of Silicon carbide or Brown fused alumina

Abrasive grains of paper base sanding belts include two types:

Silicon carbide

Brown fused alumina

View more details as below: